Reasons for choosing ‘Acoustic Materials’

H&H Acoustic Technologies Ltd can offer a wide variety of acoustic materials to aid in the controlling reverberation, reducing sound and dampening sound in numerous applications and environments. All our acoustic materials can be supplied in sheet or as cut parts to your suit your design requirements and finished in a variety of different finishes depending on the environment the material is to be used in.

Why are Acoustic Materials required and what are they?

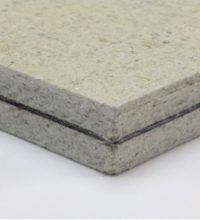

Acoustic Foams

Acoustic Foams for use in construction and architectural applications

Acoustic foams offer an excellent way of controlling reverberation within most spaces due to the nature of the open cell structure that is formed during the manufacturing process. The main key advantages of foams are:

- Available in a number of different density's (9kg/m³ upwards)

- Available in different grades to suit different acoustic and fire rating requirements

- Can be supplied in sheets or as bespoke size’s and shapes

- Finished in a variety of different ways utilizing facing materials and fabrics to suit your requirements

- Easy to install and maintain

The two main foams used within construction and the architectural industries are (with further technical information available from our product data sheets):

- Melatech® - open cell melamine foam

- Abfoam NF - open celled polyurethane foam

Melatech®

Is an extremely lightweight melamine acoustic foam (approx. 9kg/m³) that can be supplied as a sheet material in various sizes and thicknesses as well as cut and shaped parts. Given the weight Melatech® is an ideal acoustic foam for fixing to ceilings and high level applications and can be fixed using a number of differing methods depending on the application required and the environment that needs to be treated.

Melatech® sheets are converted from a block of the acoustic foam (2530mm x 1230mm x 510mm) and can be supplied in sheet form in thicknesses ranging from 6mm to 150mm

Melatech® is probably, if not, the best performing acoustic absorptive foam available even at such a low density.

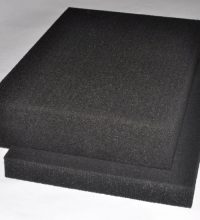

Abfoam NF

Is a polyurethane foam typically weighing 90kg/m³ given the combined weight of the foam and fire retardant treatment process the foam is subjected to. Abfoam NF is ideal for use in general building acoustics (including profiled egg box shaped foam sheets), aiding in noise transmission within mullions and other architectural sections as well as plant rooms and other industrial applications and can be supplied in sheet form and cut parts.

Abfoam NF is available in a number of differing thicknesses ranging from 6mm to 100mm and is generally supplied in sheet form up to 2000mm x 1200mm.

Abfoam NF is certified over multiple fire testing standards including EN 13501-1, BS476 parts 6&7 and ASTM E84 (further information available on our product data sheet)

Abfoam F

Is a polyurethane foam typically weighing 27kg/m³ and available in a variety of sheet thicknesses as we convert block material in house. Abfoam F is ideal for use in general building acoustics (including profiled egg box shaped foam sheets), aiding in noise transmission within other architectural designs as well as plant rooms and other industrial applications. Abfoam F can be supplied in sheet form and cut parts.

Abfoam F is available in a number of differing thicknesses ranging from 6mm to 100mm and is generally supplied in sheet form up to 2000mm x 1200mm.

Abfoam F is certified and meets HF-1 when tested to UL94 (@11mm thickness) and Crib V to BS 5852: Part 2: 1982.

Other Foam

A wide variety of alternative polyurethane, polyethylene and nitrile foams are available upon request for specialist applications.

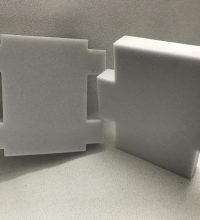

Sheets, shapes and cutting

Acoustic foam can be cut and shaped to suit multiple applications either through the use of vertical saws for simple sheets, press tooling for more complex shapes and CNC routers or profilers if a 3D or complex shape is required. For any cutting or profiling services

further assistance is available to ensure the required finish is achievable.

Melatech® can be formed in to 3D shapes such as anechoic wedges, pipe lagging etc given the raw block sizes however Abfoam NF is limited to the sheet thickness being used.

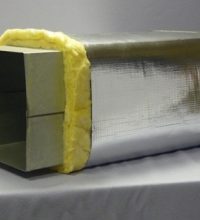

Damping sheets

Damping sheets are used in a variety of applications to deaden the effect of noise that can be transmitted along or through structures that are typically manufactured from a metal product such as steel or aluminium. Such applications can include industrial enclosures, HVAC, white goods, automotive and agricultural.

Damping sheets can also be used in conjunction with other materials such as sewn fibre quilts to form lagging materials or in sheet form acting as a mass layer barrier.

Damping sheet material is supplied with a self adhesive to one face.

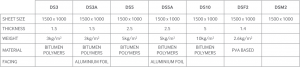

Damping sheets can be supplied in sheet form or cut to shape through the use of die cut tooling. Damping Sheets available are as follows:

Barrier mats

Barrier Mats are used in a variety of applications to reduce the effect of noise through the addition of mass to an existing structure or space and manufactured from a flexible and durable polymeric material.

Such applications can include industrial enclosures, HVAC, bulkheads, vehicle floors and composite materials and are generally supplied in sheet form although it may be possible to die cut these parts.

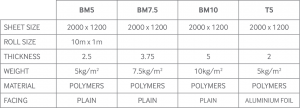

Barrier mats available are as follows:

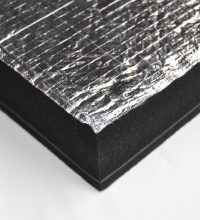

Coustilam

Coustilam is a range of laminated products that consist of a mass layer barrier sandwiched between 2 layers of acoustic foam as the core laminated product. Coustilam can then be treated with a wide variety of facing materials to suit the application and environment . The mix of sound absorbing acoustic foam and a mass layer barrier make this the ideal product for problem areas where there is a need to provide both a sound reduction and reverberation control solution.

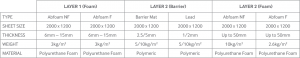

Coustilam generally consists of a thin foam layer (6mm to 15mm) that acts as a decoupling layer, a 5kg or 10kg mass barrier material and a thicker foam layer (up to 50mm) that acts as the absorptive layer as shown in the table below.

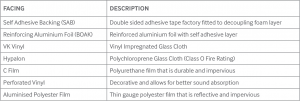

The Coustilam core can then be treated with the following materials from our standard range, although other materials may also be suitable for bespoke applications. The thick absorptive layer of foam can also be supplied in an egg box type profile if required.

Coustilam can also be supplied using other acoustic foams with further details available upon request.

As well as a comprehensive range of acoustic materials, H&H Acoustic Technologies Ltd can supply a range of acoustic flooring and wall/ ceiling treatments to resolve sound reduction issues.

We also are able to provide full support and acoustic testing through our fully qualified acoustic consultant.

For further information and assistance please contact Neil Crook at H&H Acoustic Technologies Ltd, 23 Princewood Road, Earlstree Industrial Estate, Corby, Northamptonshire NN17 4AP

Tel: +44 (0)1536 270 450 Email: neil.crook@acoustictechnologies.co.uk